Mechanical tests :

Mechanical tests aim to characterise the behaviour of materials. They provide very accurate information on the behaviour of the part or specimen under stress, and quantify its deformation in a very precise way.

CMEM offers a very comprehensive range of mechanical testing methods including: tensile, bend, resilience, and hardness testing, photomacrography, photomicrography, etc.

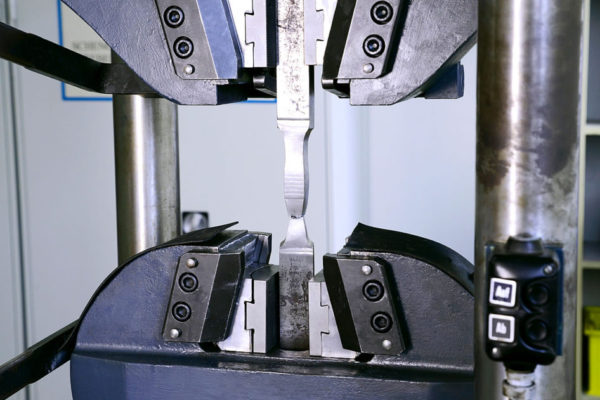

Our computer controlled tensile and compression machine can exert forces of up to 300 kN. Tensile tests may be performed at constant deformation rate, or constant or variable speed rates, in compliance with the main standards.

This test is carried out on the tensile machine. A specimen is subjected to a plastic deformation by a unidirectional bending, so that only one of the transverse surfaces or cross sections is stretched.

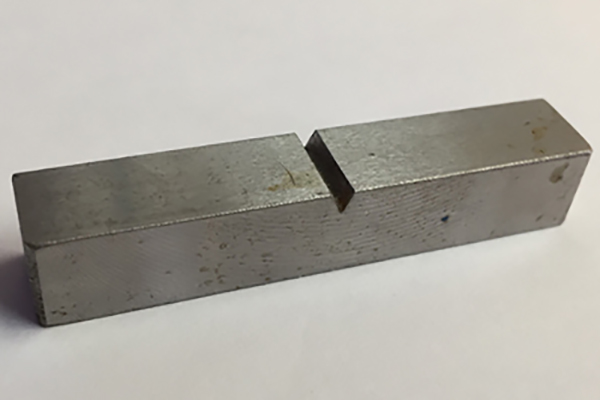

Resilience testing is complementary to tensile testing. It measures a material’s resistance to brittle fracture. The testing is performed using a 150J-300J pendulum at temperatures down to -80°C.

Texture testing provides information on the types, sizes and distribution of internal defects such as porosity, cracks, lack of fusion, incomplete penetration, and solid inclusions on the fracture surface of a weld.

CMEM performs macro and micro hardness testing, including Brinell, Rockwell, Knoop, and Vickers.

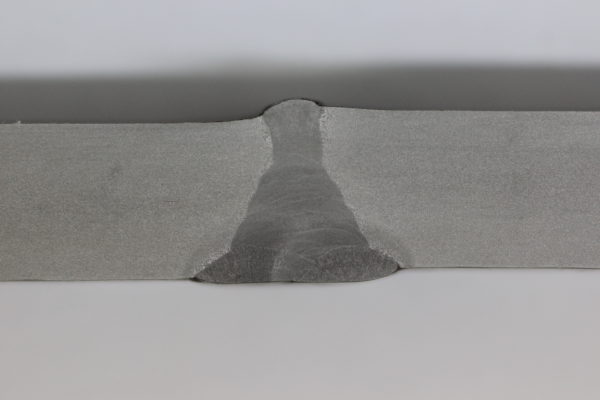

CMEM is equipped with a photo-macrographic bench used to examine the homogeneous or heterogeneous metallographic structure of a welded specimen’s cross-section. The chemical reagent applied on the polished surface of the specimen reveals the physical and chemical heterogeneity of the examined metal surface. The magnifacation value is less than GX 100.

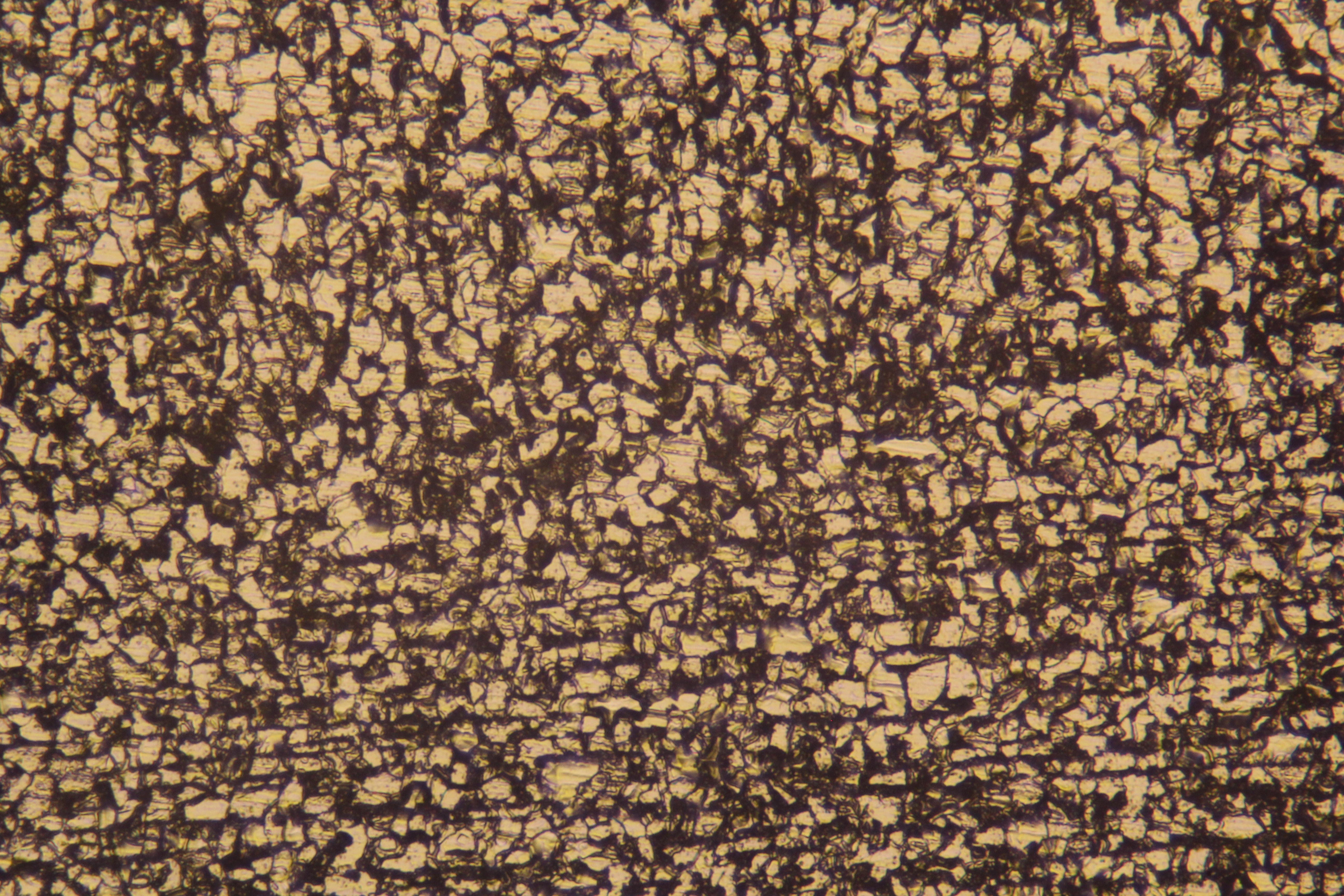

With an optical microscope and a video camera, it is possible to visualise all types of surfaces with a magnification of up to 100 times. A precise analysis is conducted through numerous observations and a good knowledge of solid physics and material phase diagrams.